Labelling Jargon

Labelling Jargon

In the world of labelling and printing, there are lots of phrases we use on a regular basis that may not be familiar to you, our visitor. Here’s your guide to the labelling jargon you’re likely to hear.

Even clients of ours who are well-versed in the lingo sometimes surprise us by wanting to know exactly what we mean by particular terms we might simply take for granted.

So we thought it’s about time someone came up with a handy “jargon buster” to explain what it is we actually mean by some of the labelling jargon you’ll find in our industry.

| Proof | A common term that means a prototype version of a label (usually just an electronic image file) that is developed in order to be checked by the customer for accuracy. Once the proof version is approved, the label is ready for production. The last thing you or I want is a spelling mistake on 100,000 labels and proofs are our way to prevent it. |

| Face Stock |

|

| A layer of paper, film or other material that makes up the “front facing” part of the label. It will usually have a layer of adhesive or glue on the backing, with the viewable words and imagery printed onto the Face Stock. | |

| Plates | Usually made of plastic – though sometimes made of other materials such as rubber or metal – plates are used to transfer the ink to the label being printed. |

| Applicator |

|

| A machine that applies pressure sensitive labels onto an item that is being labelled. (Pressure sensitive labels being the type that stick to the item when you press them onto the item). Often this is a machine that automatically applies the labels – sometimes it refers to a handheld device that is used for labelling. | |

| Kraft Backing | Krafting is the process of converting wood into wood pulp. This material can then be made into kraft paper, which is stronger and more durable than ordinary paper. It can be used for Kraft backing paper – often used in the process of picture framing. Not often used with label printers as Kraft paper is thick and doesn’t work well with the sensors that printers use to sense the cap between labels. |

| Removable Adhesive | A type of adhesive (“glue”) that allows the label to be removed from the item without leaving much residue behind. This is important for labelling high gloss items such as glass or giftware. For example, the type of adhesive used on sticky writing (post it) notes would be a removal adhesive. |

| Peelable Adhesive | This is essentially another term for “removable adhesive”. It refers to the type of adhesive (“glue”) that allows you to peel off a label from its backing as well as allowing the label to be peeled from the item it is eventually stuck on to. |

| Permanent Adhesive | An adhesive (“glue”) that binds much more strongly to the item it comes into contact with. Permanent adhesive is very difficult to remove from the item without the use of considerable force. Permanent Adhesive is the most common glue found on labels. |

| High Tack | Tackiness refers to the “stickiness” of the adhesive used on the label. A label with high tack will have a stronger adhesive and thus a high degree of “stick”. |

| DPI |

|

| Standing for Dots Per Inch, this is a well-known measure of the level of resolution for printing this isn’t specifically labelling jargon, you’ll find it in printers and software. DPI literally relating to the number of “dots of ink” that can fit along a printed line that is an inch long. (The equivalent for a computer screen would be Pixels Per Inch (PPI) – though many people use DPI to mean the same thing). Thermal label printers tend to print at 203 dpi – or 8 dots per millimeter. | |

| Label Gap | When you have a group of labels attached to a backing sheet (for example a roll of labels), the label gap is the distance between two labels. This is usually around 3mm if labels are used with thermal printers. |

| Black Mark |

|

| A Black Mark may be printed on the back of the label liner to guide certain types of printer as to where to print the label content. Black marks are essential where a label printer is printing to a clear label. Label printers use a sensor that beams a light through the relatively transparent backing paper and recognises when there is an opaque label. With a transparent label the printer needs another way to recognise the label gap. | |

| Across the Web |

|

| This refers to the number of labels across the backing sheet. If you’re using a wide printer you can print more labels at the same time and increase productivity. | |

| Cores |

|

| Tubes which the label sheets are wound around for shipping purposes. Usually made of card or plastic. They come in a range of diameters, 25mm, 44mm or 76mm, along with a range of widths. | |

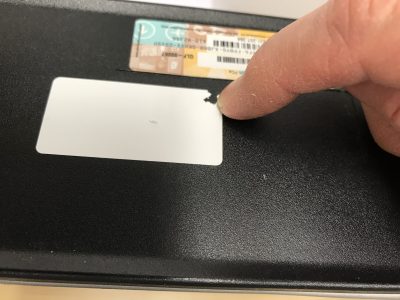

| Tamper Evident |

|

| These are labels that display evidence of any lifting or removal from the item they are attached to. They may be used for the purpose of eg preventing price labels being switched onto a different item, or for sealing boxes, computers – even doors shut – with any attempt to open the door displaying evidence of tampering on the label. See the security labels we supply here: http://expertlabels.co.uk/applications/security-labels/ | |

| Ultra Destruct |

|

| A type of tamper evident label that breaks up like an egg shell if tampered with – thus acting as an obvious deterrent to removal as it will be obviously there has been an attempt to remove the label. This type of label is demanded by the Falsified Medicines Directive. |

|

| Direct Thermal | This is talking about a type of label or tag printer. A Direct Thermal Label Printer has a print head comprising of thousands of tiny pixels. The pixels on the printhead can be independently heated. Now if you pass a heat sensitive paper or tag material underneath a hot object it will turn black. So if you take a heat sensitive paper and a printhead that can turn on thousands of different little dots, you have a way of printing! This is direct thermal – as opposed to Thermal Transfer printing. Shortcoming of direct thermal printing – is that it only works with specially coated paper or card. The labels or tags printed will turn black if subjected to heat from the sun or elsewhere. |

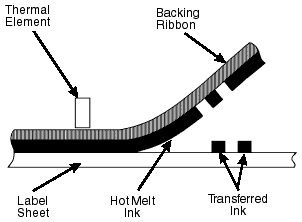

| Thermal Transfer Printing |

If you take a direct thermal printer and place a sheet of ink that melts between the print head and the label or tag you are able to melt the ink onto the label. Thermal Transfer paper have a roll of ink that melts onto the paper using a thermal printhead. |

| Printhead |

This is the part of a thermal printer that heats up and melts ink onto the label or tag. Can also heat paper coated with a heat sensitive ink that turns black when heated. |

Useful links

When it comes to barcode specific jargon, GS1, the international barcoding organisation, has a handy glossary explaining much of the barcoding, not necessarily labelling jargon:

GS1 Barcode glossary: http://xchange.gs1.org/sites/glossary/en-gb

Updated 20 Jun 2025