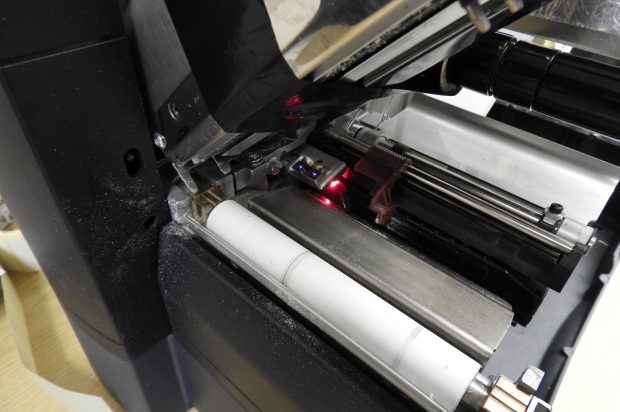

The Simple Printer Fix Most Teams Forget: Cleaning the Print Head

23rd January 2026We recently supported a team experiencing poor print quality on their thermal label printer. Their labels were coming out faint, with missing lines and unclear barcodes. Believing the printer was faulty, they began looking for a replacement. But a new printer wasn’t necessary.The problem was simply a dirty print head. It is a problem we …