Labelling for Pharmaceutical Companies

In this article...

In this article you’ll learn about Labelling for pharmaceutical companies

- What’s special about pharmaceutical labels?

- Labelling to meet the EU Falsified Medicines Directive (FMD)

- How to assure quality and traceability for pharmaceutical labels

- How to print on-demand pharmaceutical labels

- Label software for printing pharmaceutical labels

- Automatically test and verify the labels you print

- Barcode scanning

- Validating pharmaceutical labelling systems

Learn from some pharmaceutical labelling case studies

Labels for Pharmaceuticals

Pharmaceutical labels are diverse.

Braille, special cuts and extra thick booklet labels are some of the many labels we are asked to print for pharmaceutical customers.

Other requirements are for special materials that need to withstand chemical or alcohol cleaning.

Labels with Tactile Marks and Braille

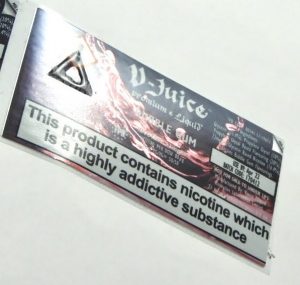

Tactile mark is the name given to a raised part of the label that can be felt with the finger tips.

In the image to the left the label has a warning triangle tactile mark.

Usually they are used to indicate to blind people that the product is potentially dangerous.

Tactile Marks are printed after the main label is printed and need a special ‘screen’ which adds to the cost of the label.

Braille is another feature that often appears on pharmaceutical labels. Braille is printed using a special varnish over the top of the label.

Booklet and Peel & Reveal Labels

Booklet labels feature regularly with Pharmaceutical labels, to include multiple languages for international products.

While lower cost peel and reveal labels are able to print up to 5 pages, booklet labels (or Fold Out Labels) can cope with many more leaves.

Not all thermal label printers can cope with thick booklet labels.

Experience has shown us the printer needs to be tested and compatible.

See the video below showing the booklet labels on the printed through a Sato CLnX thermal printer.

Cryogenic Sample Storage

Adhesives sometimes need to be able to withstand cryogenic temperatures for sample storage.

Ask us for a sample of cryogenic labels with ultra low adhesive for cryogenic storage down to temperatures of minus 196 C.

Falsified Medicines Directive and Tamper Evident Labels

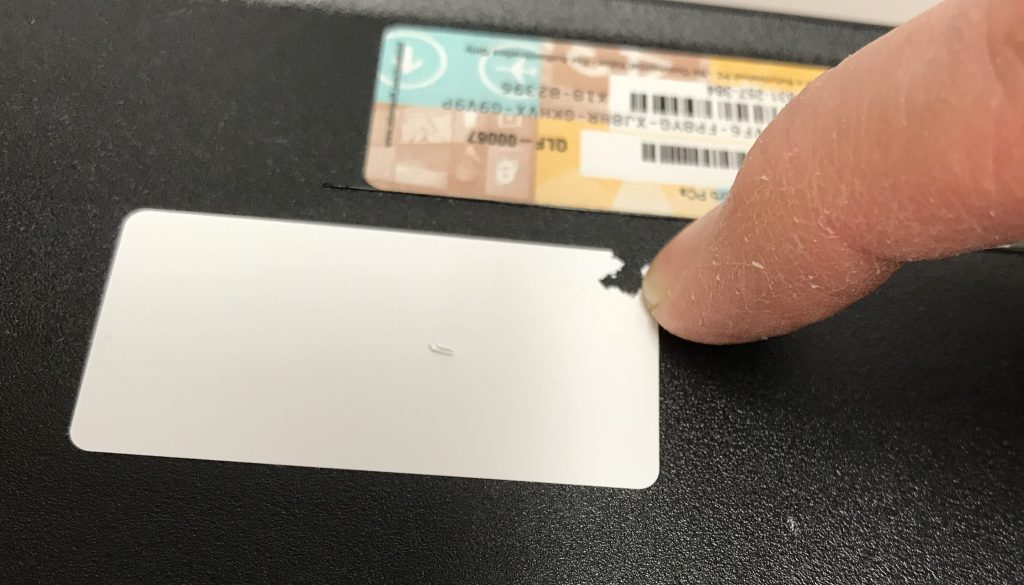

To comply with the Falsified Medicines Directive, labels need to tamper evident.

That is, clearly show the consumer that the box hasn’t been opened.

This can be done by using a special label material that breaks when the box is opened.

Alternatively a label cut with a special die that tears when it’s opened is a simple cost effective solution.

If you need to apply your labels with an applicator – you need to test these tamper evident labels before committing to large quantities.

Quality and Traceability for Pharmaceutical Labels

Quality and traceability are critical to Pharmaceutical labels – so all the labels we produce come with a certificate of conformity if you ask for one.

They are made in factories that have the highest quality standards – the BRC AA Rating – ensuring 100% traceability of materials and audited standards of hygiene not only for pharmaceuticals but food also.

Quality of print is monitored by camera systems designed to spot any non-conformance and stop production to prevent sub standard products from leaving the factory.

Material wastage is another factor in quality management processes and these are carefully monitored.

Efficient Thermal Label Printers for Pharmaceutical Printing

The most efficient and effective technology for printing labels is thermal transfer.

Thermal Transfer printers are fast, capable of printing onto single labels and reliable enough to print onto labels 24 hours a day.

Unlike laser printers, thermal label printers work with a wide range of label materials – including paper and plastics.

Thermal printers were designed in the 1970s to print barcodes and optimised for printing 1D and 2D codes (like Datamatrix and QR codes).

Our pharmaceutical customers sometimes need to print onto booklet labels. We’ve successfully tested booklet printing with Printronix and Sato printers.

Another alternative to printing onto booklet labels is to print onto clear labels and apply these to the top of the booklet label.

Labelling Software for Pharmaceutical Companies

Only a few label design software packages meet EU and FDA regulations (21 CFR Part 11) for traceability. We work with Seagull Scientific’s BarTender label design and printing system. It’s powerful enough to link to ERP programs like Oracle and SAP to make label printing automated, accurate and efficient.

Ask us about BarTender label design and printing software. With experience installing into Pharmaceutical companies – we can install, validate and train users – giving a complete turn key solution.

Automatically Test and Verify the Labels You Print

Labels can be automatically verified for quality. Using a camera and software from Omron, our customers are able to automatically monitor each label printed and verify it matches the control label.

When the camera sees a non-compliant label, the printer stops and warns the operator.

Text, images and print quality – along with barcodes – can be checked automatically and results retained for audit.

There are a few printers available with in-line barcode verifiers – but ask us about our print quality inspection systems – that scan not only the barcode by monitors for marks, scratches as well as incorrectly printed data.

Advice on Barcode Scanning

Printing labels is usually a customer requirement, but scanning barcoded labels can make your own internal operations more efficient and accurate.

With 25 years of experience with printing and scanning barcodes – let us help you choose 1D and 2D barcode scanners and handheld terminals to suit your situation.

Contact us for barcode scanning advice.

System Validation

Setting up or altering labelling systems in pharmaceutical companies can be time consuming and tedious. A comprehensive and detailed list of tests need to be compiled and tested. Steps in putting together a system validation include.

- Define a User Requirements Specification.

- Find appropriate software to complete the task

- Install and test the software

- Systematically work through a validation checklist to ensure the system works as expected.

Expert Labels are able to provide software and hardware for testing. We can help with putting together a URS and have experience compiling a validation checklist.

Ask us about validating your pharmaceutical label systems or read our article about validating your labelling system here.

Useful Links

- Barcode Labels

- Biodegradable Labels

- Block Out Labels

- Booklet and Fold out Labels

- Cryogenic Labels

- Fan-Fold Labels

- High Temperature Heat-Proof Labels and Tags

- Label Design and Print Software

- Loop Lock Labels

- Peel and Reveal Labels

- PiggyBack Labels

- RFID and Security Labels

- Security Labels

- Sustainable Labels

Get a Free Sample Pack

-

Our Products -

More Products