Document your policy: It sounds tedious, but ten minutes writing up how your artwork will be managed and the systems and processes followed will make life easier for you, your team and contractors like us.

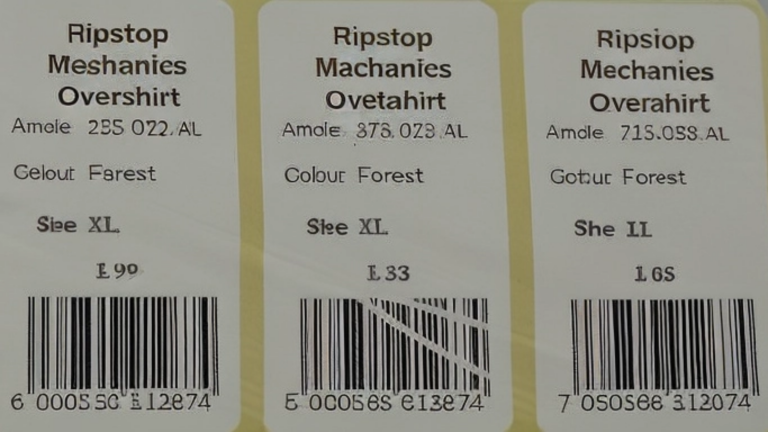

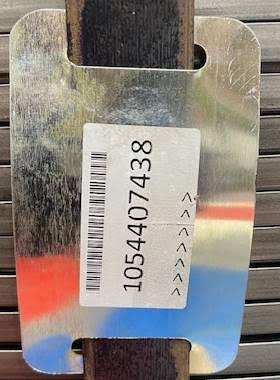

Name Your Files Consistently: Use a clear system for naming your files. Include the date, project/product name and version number. Include the label dimensions. Example: 20240805-38X25-PAR-A14563-Beautiful Brows-V2. This is the second version of the Beautiful Brows product, product code A14563 on a 38mm x 25mm Peel & Reveal label (PAR) – originally created on 5th of August 2024.

Organise Your Files: Create a simple folder structure. Sort files by product type, project, type of packaging, or client. Store files in cloud storage which can be accessed by us.

Use Metadata: Add information like title, date, and label dimensions to your files. This helps in finding and organising your designs.

Back-Up Regularly: Save copies of your files on external drives or cloud storage to prevent loss. Given that a large portfolio of artwork might have taken a team of designers months to design and is, in effect, irreplaceable, backing up is critical. That includes backing up from the cloud to local storage.

Document Your Process: Keep records of your design steps, from sketches to final versions. This helps track your progress and can be useful for future projects.

‘Retire’ artwork: When designs become obsolete, archive them so your artwork is current. Archiving rather than deleting means you can reuse designs for future projects.

Set up workflows: With BarTender Enterprise edition you can assign users with different roles – e.g. designer, approver, printer. Each role has different permissions. You can then set up workflows.