This is how to print high temperature labels – able to withstand temperatures from 200C to 1,250C – in house using your own printer. You’ll learn what label printing hardware you need, the type of thermal ink ribbon and the label design software you need to design your labels.

- Printer compatibility

- Ink selection

- What can you print?

- Label design

Label Printing Hardware

The labels we supply need to be printed using a thermal transfer printer. Thermal printers are made by Zebra, Sato, Honeywell and a host of other brands.

These printers are specially designed for label printing. They are fast and extremely reliable.

Thermal Transfer printers use a roll of ink ribbon that melts onto your label. They are single colour – depending on the colour of the ink ribbon. 99% of the ribbons we sell are black, but can come in other colours.

Thermal printers range in price from £500 to £1500 depending on how big, fast, durable and flexible they are.

Ink Selection

Ink ribbons for standard high temperature labels (sub 400C) come in three lengths – 74m, 300m and 450m – depending on your printer.

These ribbons are made from resin and come in boxes of at least six rolls. It is possible to get different coloured ink ribbons – though there are quite high minimum order quantities.

The ultra-high-temperature labels (designed to withstand temperatures up to 1250C) need a specialist ink. These are only black and come on rolls of 300m. This makes them compatible with all industrial sized printers and many of the desktop models.

Ultra-high-temperature inks are more expensive than standard ribbons and come in units of single rolls.

Are There Any Limitations About What I Can Print?

You are limited to printing just one colour – usually black.

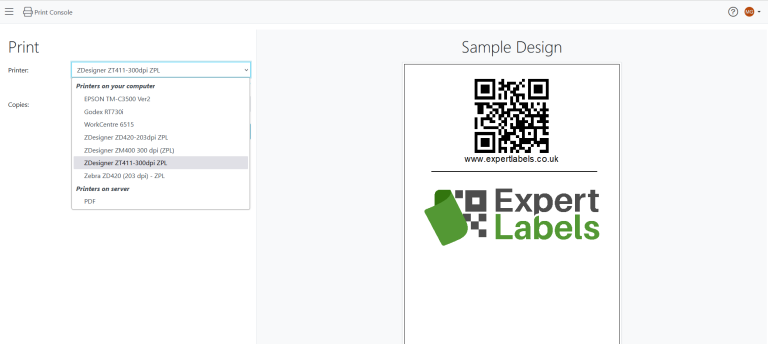

You can print standard linear barcodes, QR Codes and other 2D barcodes. You can print logos and text. Depending on your printer resolution, it’s possible to print text down to around 5 points size.

Depending on your label design software, it’s possible to print any font or language.

Each of your labels can be unique. Serial numbers and date codes can be included.

Thermal label printers range in print resolution from 200 dpi to 600dpi. Most printers are 200 or 300 dpi. 300 dpi printers produce images of good resolution acceptable for most industrial uses.

Designing Your Labels

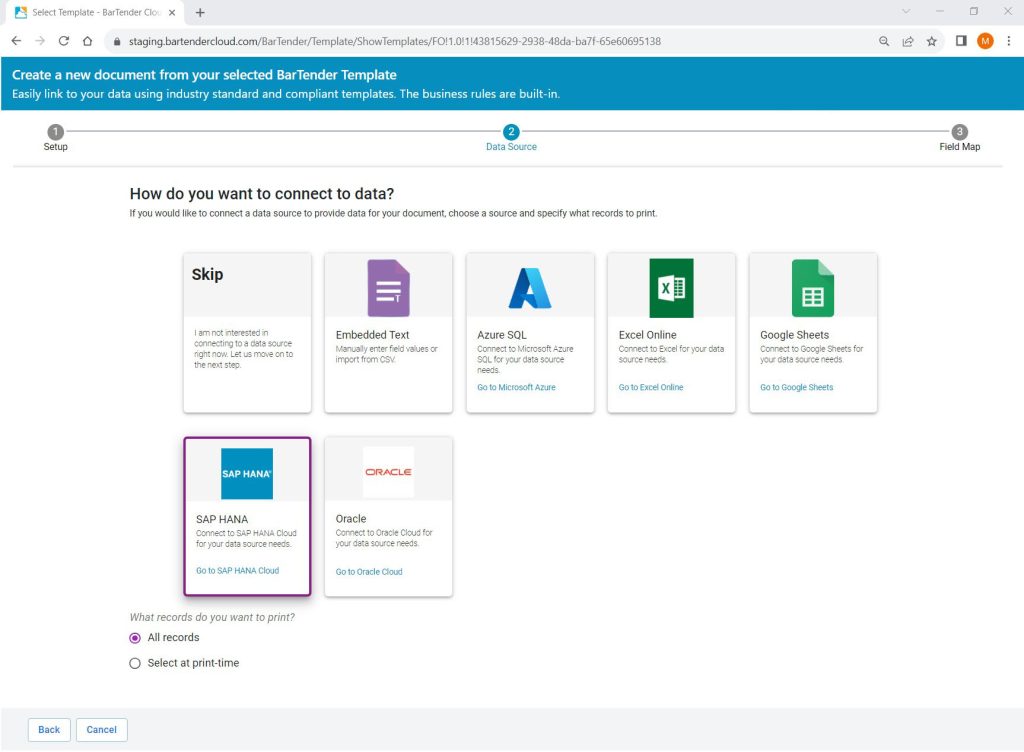

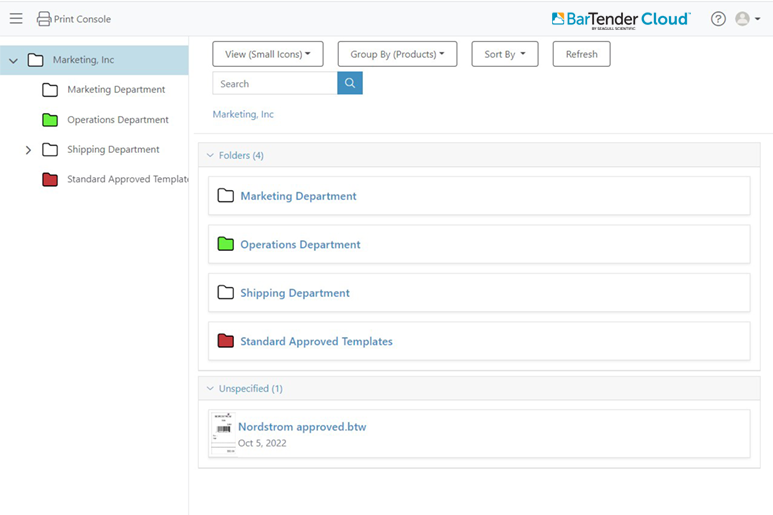

Labels can be designed by you, using label design software from Zebra (Zebra Designer), Seagull Scientific (BarTender) or Loftware (Nicelabel).

These programmes can design labels with barcodes, text, and graphics.

Using this software, you can link to databases – from Excel to SAP and Oracle.

Check our guide to label design software to see the full range of capabilities.

Page updated: 11 Jun 24