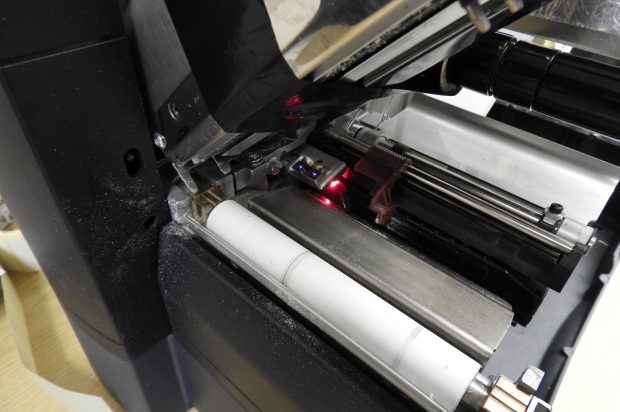

The Simple Printer Fix Most Teams Forget: Cleaning the Print Head

The Simple Printer Fix Most Teams Forget: Cleaning the Print Head

BarTender Label Design & Print Software

BarTender Label Design & Print Software

How to Clean and Maintain Your Label Printer (Simple Guide)

How to Clean and Maintain Your Label Printer (Simple Guide)

Bartender Allergen Hack

Bartender Allergen Hack

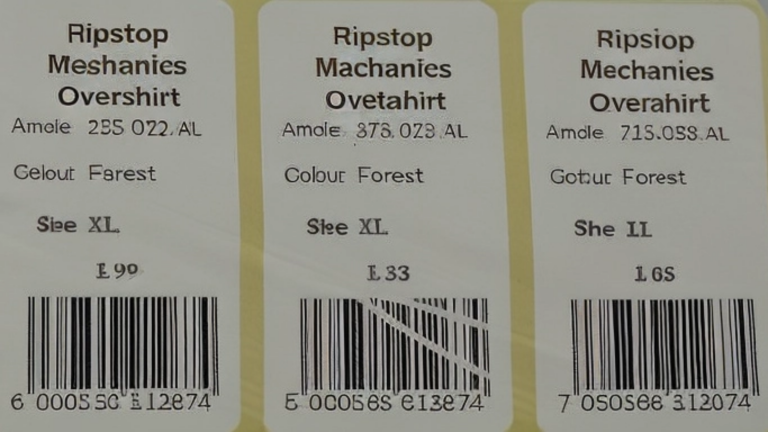

Are you struggling to design labels that meet the EU’s Food Information Regulations? Is the need to highlight potential allergens giving you a headache? World leading label design software, BarTender by Seagull Scientific has a handy hack that will mean your list of ingredients can be created easily and automatically with the allergen’s in bold. Read on to find out how.

The EU’s Food Information for Consumers Regulation states:

“The allergenic ingredients need to be emphasised using a typeset that clearly distinguishes it from the rest of the ingredients, for example by means of the font, style or background colour. Food businesses can choose what method they want to use to emphasise the 14 allergens on their product label.”

That’s simple enough when you’ve got a few labels to print – but how do you do it when you’ve hundreds of label designs?

How to design labels with Allergen’s highlighted

Download the step by step instructions

Download the files you need

Useful links

What needs to appear on a food label

UK Government Food Labelling regulations.

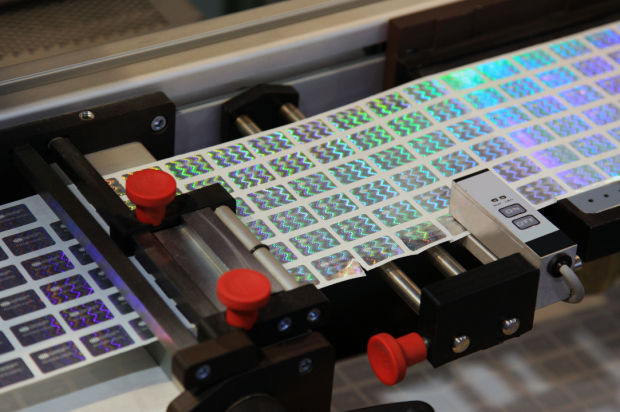

Over printing services

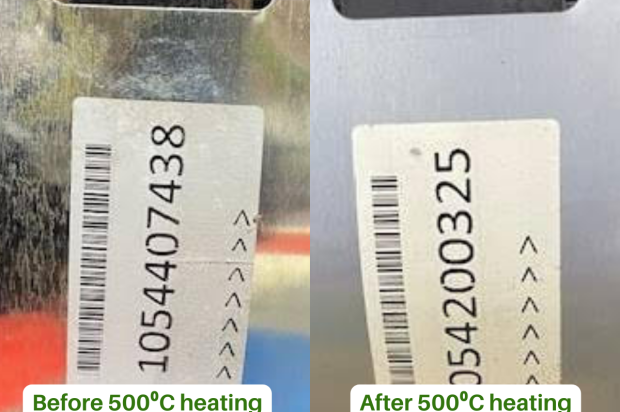

Materials Used in High-Temperature Labels

Materials Used in High-Temperature Labels

What We’ve Learned About Label Adhesives in Extreme Conditions

What We’ve Learned About Label Adhesives in Extreme Conditions

Mistakes Businesses Make Integrating Label Printing Software

Mistakes Businesses Make Integrating Label Printing Software

Common Mistakes When Choosing Labels for High-Abrasion Surfaces

Common Mistakes When Choosing Labels for High-Abrasion Surfaces

5 Key Lessons Learned from Label Printing Failures

5 Key Lessons Learned from Label Printing Failures

Labelling Regulations: A Comprehensive Overview for Pharma